Equipment Condition Monitoring

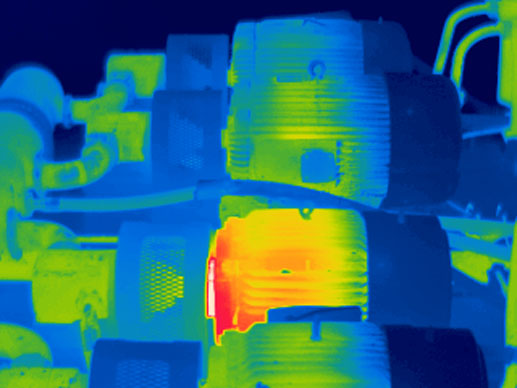

Any unplanned machinery downtime can be costly and disruptive to your business. Our expert technicians employ cutting-edge thermal imaging technology to inspect your equipment, ensuring reliable and actionable insights into your equipment's health and performance, helping keep your machinery running efficiently and to detect any potential issues before they escalate into costly repairs or breakdowns.

Why use Thermal Imaging for Condition Monitoring?

Thermal imaging is a non-invasive diagnostic technique designed to detect temperature variations within your equipment. These variations can often signal underlying issues that aren't visible to the naked eye, giving you time to address them proactively.

Prevent Failures Early

Thermal imaging enables early detection of problems such as overheating bearings, electrical hotspots, equipment misalignments, and insulation failures. By resolving these issues before they have a chance to lead to costly downtimes, you can maintain an uninterrupted industrial operation.

Optimise Maintenance Schedules

Move from a reactive to a proactive maintenance strategy by focusing your efforts on machinery that is showing signs of stress or wear. With thermal imaging, you only service the equipment that truly needs attention, optimising your maintenance schedules and resources.

Enhance Safety Standards

Thermal imaging inspections can play a crucial role in identifying hazardous ezuipment failures before they happen. Helping to prevent scenarios that might compromise the safety of your workforce. By addressing these potential threats, you create a safer working environment for everyone involved.

Save on costs

By addressing minor issues detected through thermal imaging before they escalate, you avoid expensive repairs and equipment replacements. This proactive approach not only saves money but can help prevent downtime in the future.

See How We Conduct Our Equipment Monitoring Surveys

We offer a quick and efficient service to identify problem areas and provide you tailored information to rectify any issues

Initial Assessment

Step One

Once we arrive on site we will walk through the site with you to identify any equipment of concern and present an inspection plan covering all equipment to be inspected.

Equipment Inspection

Step Two

We will conduct thermal imaging of all required equipment identified, looking for any indications of improper operation and potential points of failure. Conducting our inspection does not require any machine downtime as the equipment needs to be observed under normal operating conditions.

Inspection Findings and Remediation Steps

Step 3

Once we have completed our assessment we will walk you through our findings and we will advise on any potential issues or remediation that should be taken as well as prepare a full report of all issues.

Ready To Get Insights On Your Equipment Health?

Book your survey today and get insights to help reduce downtime and replacement costs